Herzlich willkommen bei

cnc adam

Schön, dass Sie uns online besuchen. Gerne informieren wir Sie über unser Leistungsspektrum.

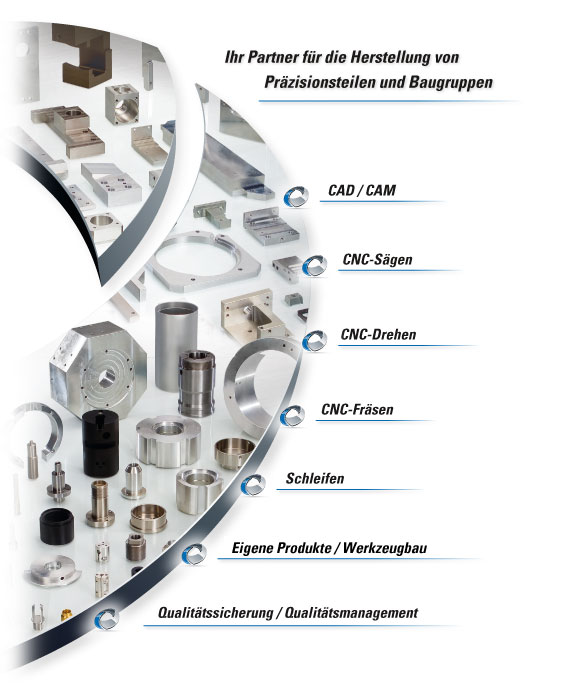

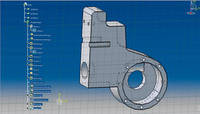

Ihr Partner für die Herstellung von Präzisionsteilen und Baugruppen

CNC ADAM

Die Adam GmbH + Co. KG, mit Firmensitz in Suhl – Gewerbegebiet Friedberg, stellt seit 1998 für unterschiedliche Industriebereiche Baugruppen und Präzisionsteile aus verschiedenen Materialien nach Kundenvorgaben bis zur mittleren Serie her.

512+

Projekte gemeinsam mit unseren Kunden entwickelt.

35.646+

Aufträge erfolgreich abgeschlossen.

No. 1

eigenes Produkt:

CNC -Stangengreifer

Firmenporträt

Unsere Produkte werden im Sondermaschinenbau, der Medizintechnik, der Luftfahrtechnik, der Automobilindustrie, der Optik und in der Solarindustrie eingesetzt.

Mit qualifiziertem Fachpersonal in der Konstruktion und Fertigung, sowie mit universalen CNC-gesteuerten Werkzeugmaschinen der neuesten Generation garantieren wir prozesssicher eine hohe Funktionalität, Maßhaltigkeit, sowie Oberflächengüte unserer Erzeugnisse nach den höchsten Ansprüchen unserer Kunden.

Die Qualität einzelner Arbeitsschritte, fertiger Erzeugnisse oder Funktionalität der Baugruppen kann mit Prüfberichten dokumentiert werden. Zum Einsatz kommt hier u.a. moderne Software und CNC-gesteuerte Koordinatenmesstechnik von Zeiss.

Unser Unternehmen ist seit 1999 zertifiziert und wird regelmäßig vom TÜV Thüringen und unseren Kunden auditiert.

Weitere Dienstleistungen wie Oberflächenbeschichtungen oder Stoffeigenschaftsänderungen führen wir in Kooperation mit geprüften und zuverlässigen Partnerfirmen durch.

CNC-Fräsen

3 Achs-Bearbeitungszentrum:

- Standard – Fräsoperationen

Bearbeitungsmöglichkeiten:

- CNC-Fräsen und Bohren mit Hochdruckkühlung durch die Frässpindel für Werkzeuge mit Innenkühlung

- Synchrones Gewindebohren und Gewindeformen

- Freiformfräsen von 3D-Konturen

5 Achs-Bearbeitungszentrum:

- 5-Seiten Komplettbearbeitung für Form- und Lagetoleranzen mit höchster Präzision

- 5-Achs-Simultan Fräsoperation

- Automatisches Be- und Entladen von Werkstücken

Bearbeitungsmöglichkeiten:

- CNC-Fräsen und Bohren mit Hochdruckkühlung durch die Frässpindel für Werkzeuge mit Innenkühlung

- Synchrones Gewindebohren und Gewindeformen

- Freiformfräsen von 3D-Konturen

Die Fertigung erfolgt mit CNC-Fräsmaschinen der neuesten Generation.

CNC-Fräsmaschinen 3-Achs Werkstückparameter:

|

x-Achse: |

1110 mm |

|

y-Achse: |

510 mm |

|

z-Achse: |

510 mm |

CNC-Fräsmaschine 5-Achs-Bearbeitungszentrum Werkstückparameter:

|

x-Achse: |

500 mm |

|

y-Achse: |

500 mm |

|

z-Achse: |

500 mm |

Die Fertigung erfolgt mit CNC-Dreh- / Fräsbearbeitungszentren und CNC-Revolverdrehmaschinen der neuesten Generation.

Werkstückparameter:

|

Bearbeitungsdurchmesser: |

10 – 300 mm |

|

Bearbeitungslänge (max.): |

400 mm |

|

Spindeldurchlass (max.): |

Ø 100 mm |

|

Mehrkanal-Stangenlader: |

Ø 10 – 80 mm |

CNC-Drehen

5 Achs-Dreh-Fräsbearbeitungszentren:

- Bearbeitung mit Multitasking-Werkzeugen

- Komplettbearbeitungen in einer Aufspannung

- Übergabe 2. Spindel (vollwertige C-Achse)

- Y- und B-Achsensteuerung

- Vollwertige Frässpindel

- Hochdruckkühlung durch Frässpindel für Werkzeuge mit Innenkühlung

- Winkelflächenbearbeitung mit komplexen Geometrien und Taschen

- Freiformfräsen von 3D-Konturen mit 5-Achsensimultanbearbeitung

- Automatischer Reitstock

3 Achs-Revolverdrehmaschinen:

- Futter- und Spannzangenspannung

- angetriebene Werkzeuge

- Bohr- und Fräsbearbeitungen

- Automatischer Reitstock

CNC-Sägen

Mit Sägeautomaten

Zum Sägen von Material werden vollautomatische Bandsägeautomaten eingesetzt.

Wir können Materialzuschnitte in allen Stückzahlbereichen mit Prüfzeugnis zu günstigen Preisen anbieten. Die wichtigsten Materialabmessungen und Materialgüten haben wir vorrätig.

Unser Anspruch: Eine Woche nach Auftragseingang liefern wir, je nach Menge, die Zuschnitte mit Materialzeugnis an.

Spezifikationen Bandsägeautomaten:

- Automatische Bandverlaufskontrolle

- Berührungsloser Null-Anschlag - Sägen ohne Anschnittverluste

- Bündelspannung

- Rollenbahnen mit Geradführung der Stangen

- Zuschnitt-Reinigung direkt nach dem Absägen

- Sägen in mannloser Schicht

Materialabmessungen: 10 – 320 mm

Zuschnittlänge: 2 – 680 mm

Werkzeugbau

Konstruktion und Herstellung von:

- Baugruppen

- Spann- und Montagevorrichtungen nach Kundenvorgaben

- Herstellung von Formeinsätzen für Spritzwerkzeuge, Nietwerkzeuge, Stanz- und Biegewerkzeugen

Eigene Entwicklung und Herstellung von einem Stangengreifersystem für CNC-Drehmaschinen.

Der Stangengreifer ist ein Greifwerkzeug zum herausziehen von Stangenmaterial Ø 3 – 90 mm aus dem Futter der CNC-Drehmaschine bzw. CNC-Bearbeitungszentrum im Automatikbetrieb.

Eignet sich besonders für:

- Fertigung von kleinen und mittleren Serien von Stangen und

- sogar zum Transfer von Werkstücken

Er wurde bei uns 1998 entwickelt und ist seither erfolgreich bei Kunden und in unserer eigenen Fertigung im Einsatz.

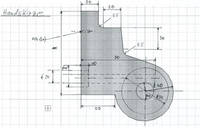

CAD / CAM

Das bedeutet für unsere Kunden:

kurze Lieferzeiten, schnelle Verfügbarkeit und geringe Herstellungskosten.

Qualität

Maximaler Qualitätsstandard durch unser praktiziertes Qualitäts-Management.

- Wir sind zertifiziert nach DIN EN ISO 9001/2015

- Eigene Qualitätssicherung zur Wahrung der ISO-Standards

- Klimatisierter Messraum

- Einsatz modernster CNC-Koordinatenmesstechnik der Firma Zeiss mit Software zur Erstellung von Mess- und Prüfberichten

- Automatisiere Prüfprozesse – maximale Wiederholgenauigkeit

- Automatisierte Erstellung von Prüfberichten / Prüfprotokollen

Referenzen

Ein kleiner Eindruck in das Tätigkeitsprofil in welchen Branchen wir unsere Kunden mit Präzisionsteilen beliefern.